- Home

- About

- Products

-

Globe Control Valve

Butterfly Valve

Ball Valves

Gate Valve

Globe Valve

- Products

- Global Presence

- Customer Care

- Our Client

- Career

- Contact Us

- Download

- Enquiry

Size & Rating

#150

48 Inch | DN 1200

#300

36 Inch | DN 900

#600

30 Inch | DN 750

Description

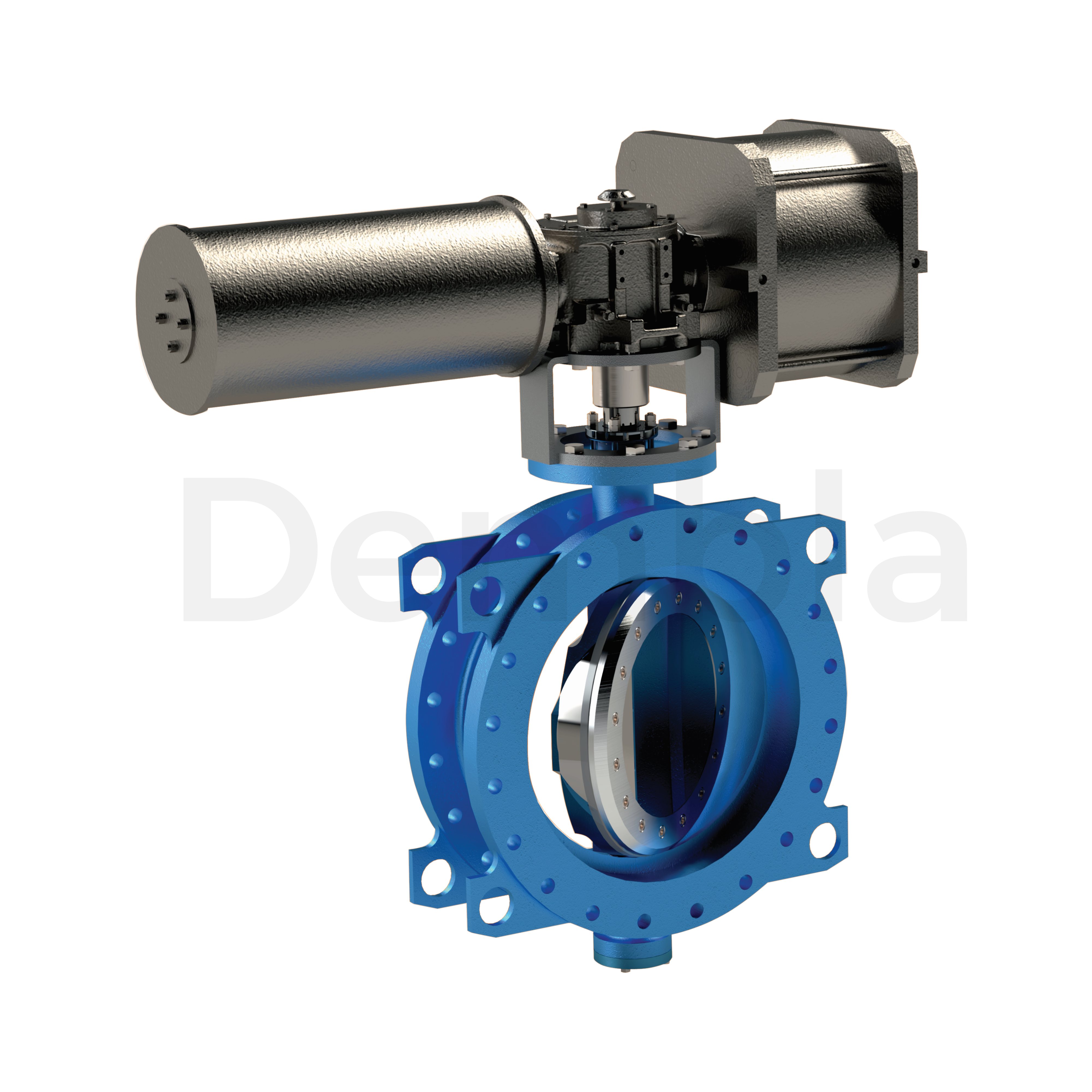

Butterfly valves with single or double offset construction do not perform to the expectations when used for harsh & severe process applications, such as extreme temperature conditions, steam isolation, high operational frequency, abrasion services etc. Triple offset butterfly valves provide reliable & efficient performance under these harsh applications.

Series 7600 Triple offset metal seated Butterfly valves with unique seating geometry & design disc-shaft engagement provide high cycle life under extreme temperature conditions. With metal to metal tight shut-off characteristics eliminates.

Features

Metal Seated Rate 'A' as per ISO 5208

Metal to metal Tight shut-off

Inherently Fire Safe Design

Laminated Seals

Suitable to handle high temperature and abrasive application

Bidirectional

Anti Blow out stem design

Cryogenic application valve available

Double Eccentric Disc design impart extremely high Edge to suit various demanding applications

Design

API 609,B 16.34

F/F

API609/EN 558

Testing

API-598/EN-12266

API-607

End Connection

FLANGE/WAFER/ LUG-B16.5,B16.47,EN1092-1

BUTTWELD-B16.25

Size

DN 80 Thru DN 1200

3" Thru 48"

Working Temperature

-29oC to + 538oC

With suitable combination of materials

-100oC to + 700oC

Body Styles

Lug Types and Double Flanged

Actuators

Manual Gear Operator, Pneumatic Actuator, Electrical actuator

Applicable standards

Design

Basic Design as per API 609

Calculations according to ASME SEC. VIII,

EN-12516-2

ASME SEC. III, ANSI B16.34

Face to Face Dimension

API 609 / EN 558-1 Series 13 & 20

Body Flange

ANSI B16.5,ANSI 150# ,ANSI 300#

Drilling

PN-10,16,25,40

Marking

MSS-SP-25 / EN 99

Quality

ISO 9001

Material

|

MATERIAL |

CASTING |

FORGING |

|

CARBON STEEL |

A216 Gr. WCB, A217 Gr. WC6, A217 Gr. WC9 |

A105 |

|

LOW TEMP CARBON STEEL |

A352 Gr. LCB, A352 Gr. LCC |

A350 Gr. LF2 |

|

STAINLESS STEEL |

A351 Gr. CF8M, A351 Gr. CF8, A351 Gr. CF3M, A351 Gr. CF3 |

A182 Gr. F316, A182 Gr. F304, A182 Gr. F316L, A182 Gr. F304L |

|

DUPLEX |

A995 Gr. 4A |

A182 Gr. F51 |

|

SUPERDUPLEX |

A995 Gr. 5A, A995 Gr. 6A |

A182 Gr. F55 |

|

HAST C |

A494 Gr. CW-12MW |

B574 UNS N10276 |

|

ALLOY 20 |

A351 Gr. CN7M |

B462 Gr. N08020 |

|

BRONZE |

B62 Gr. C83600 |

|

|

ALUMINIUM BRONZE |

B148 Gr. A |

B150 Gr. C62300 |

|

NICKEL AL BRONZE |

B148 Gr. D |

B150 Gr. C62300 |

|

TITANIUM |

B381 |

B381 |

|

MONEL |

MONEL 400, MONEL K-500 |

MONEL 400, MONEL K-500 |

|

NICKEL |

INCONEL 625, INCONEL 825, INCONEL 718, INCONEL X750 |

Application Industries

Chemicals & Natural Gas

Power Plants

Sugar Mills

Paper and Pulp

Water

Food & Beverage

Petrochemicals

Oil and gas

Gas Process

Piping Systems

Ship Building

FPSO

Pharmaceuticals

Mining

Size & Rating

150#

64 Inch | DN 1600

300#

48 Inch | DN 1200

600#

36 Inch | DN 900

900#

24 Inch | DN 600

Description

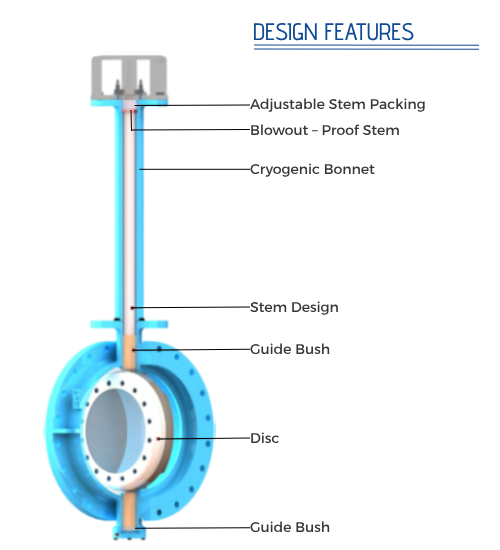

Dembla Triple Offset Cryogenic Butterfly Valves are designed & manufactured for tight shut off and throttling service. This reduces wear and tear on the sealing and extends its service life. The bonnet is extended to ensure that the gland area remains free from freezing even for temperature down to -196°C. By adopting the most advanced design concept, high precision processing control and excellent process management, the low temperature cryogenic butterfly valves have many outstanding advantages, such as reliable sealing, high stability at low temperature and long service life.

Features

Height of the extended bonnet suitably designed to keep away stuffing box from cryogenic surfaces. This avoids the failure of seals due to low temperature effect.

Laminated and solid metal seat designs available.

Minimum extension height is 700mm or larger.

Tight Shut - off (Class VI) leakage.

Seal Ring

There are two seat variations available depending upon the application and service requirements

Laminated Metal Seal provides an independent seal, unaffected by damage to the others.

Solid Metal Seal for high temperature and severe application

TRIPPLE OFFSET BUTTERFLY VALVE SOLID LAMINATED

TRIPPLE OFFSET LAMINATED

Design

BS 6364, API 609 , EN 593

Face to Face

API 609 , EN 558

Flange End

ASME B16.5 , ASME B16.47 , BS EN 1092-1

Test and Inspection

ISO 5208, API-598 , EN 12266-1

MATERIAL

LIMITING TEMPERATURE

A352 LC3

-101℃

A351 CF8

-254℃

A351 CF8M

-254℃

A351 CF3

-254℃

A351 CF3M

-254℃

Application Industries

Oil and gas

Power Plants

Chemicals

Petrochemical

Marine

Global Presence of Dembla

Dembla is one of the major Manufacturer, Exporter and Supplier of Ball Valve, Butterfly Valve, Globe Control Valve, Globe Valve, Check Valve, Gate Valve, DBB Valve, Dual Plate Check Valve, in Italy, Germany, France, Japan, Brazil, Chile, Canada, Australia, Indonesia, Philippines, Vietnam, Africa, Spain, Turkey, Netherlands, UK and across the Entire Globe.

Our Manufacturing set up is situated at Bhiwandi, Thane - Mumbai, Maharashtra, India.