- Home

- About

- Products

-

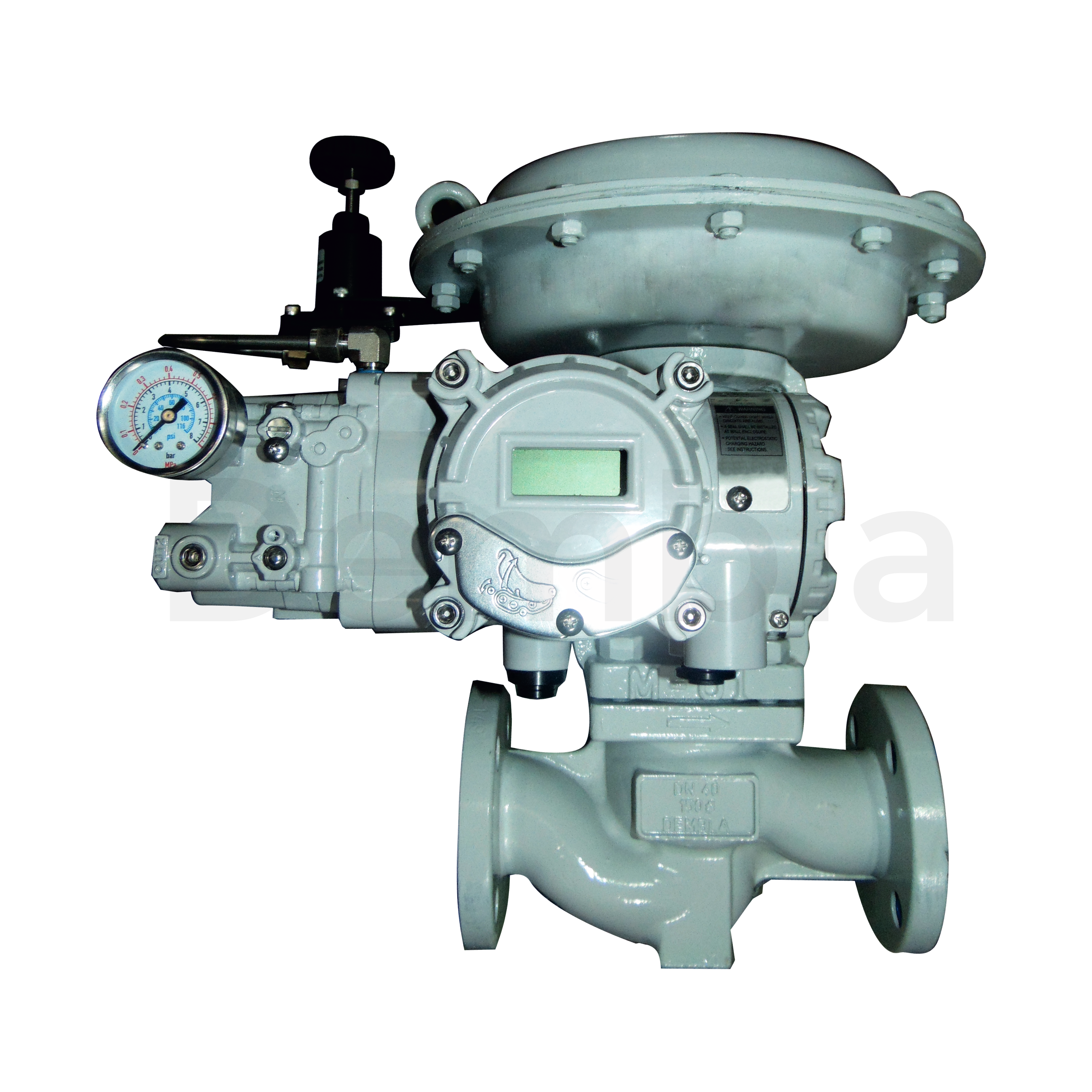

Globe Control Valve

Butterfly Valve

Ball Valves

Gate Valve

Globe Valve

- Products

- Global Presence

- Customer Care

- Our Client

- Career

- Contact Us

- Download

- Enquiry

Size & Rating

150#, PN10, PN16, PN20

1/2 Inch - 4 Inch

Description

Series 1200 Globe Control Valves are compact design with bolted bonnet .The design facilitates easy access to internal components, online inspection and maintenance. The reduced port option provide nearest accurate selection of trims. These are provided with Multi Spring Diaphragm Actuator for reliable shut off & flow control performance.

Specifications

Bonnet Type:

Standard

Flow Characteristics:

Linear

Equal

On-Off

Body Gaskets:

S.S. Spiral wound with Graphite Filled.

S.S. Spiral wound with PTFE Filled.

Gland Packing:

PTFE : -150oC to +200oC

Graphite : -150oC to +600oC

Hysteresis error :

Without positioner : within +5% F.S.

With positioner : within +1% F.S.

Linearity :

Without positioner : within +5% F.S.

With positioner : within +1% F.S.

Nominal Valve Size:

NPS ½, ¾, 1, 1.¼ , 1.½ , 2, 2.½ , 3, 4.

DN 15, DN 20, DN 25, DN32, DN 40, DN 50,

DN 65,DN 80, DN 100.

Pressure rating:

ANSI Class 150

PN 10,16,20

End connection:

Flanged end; FF, RF

Valve Body MOC:

Carbon Steel ASTM A216 Gr. WCB, Alloy Carbon Steel ASTM A217 Gr . WC1, WC6, WC9, C5, C12, A352 LCB, LCC, LC3, Stainless Steel ASTM A351 Gr. CF8, CF8M, CF3, CF3M, CF8C, Alloy Steel Hast 'C', Alloy 20, Nickel, Titanium, Monel, etc All other Materials available on request.

Trim Type :

Contour Top Bush Guided, Disc Top Bush Guided Trim (DN15 to DN100).

M.H.Cage Pressure Balanced Trim Only DN100

Trim MOC :

Stainless Steel ASTM A479 Type SS316, SS304, SS316L, SS304L, Hast 'C' Alloy 20, Nickel, Titanium.

All other Material available on request.

Rangeability :

30:1

CV Curves :

Refer Table 2

Seat Leakage:

As per ANSI/FCI 70-2 Class IV (With Metal to Metal Seating) (Class V-With Metal to Metal to Metal) (Stellite Faced Trims available on request).

Hydro Test Pressure:

1.5 times of rated pressure.

Actuator Type Action :

Direct Acting & Reverse Acting.

Diaphragm :

Nitrile with Nylon fabric insert.

Actuator Model No. :

M-00-16/MP-00-16

M-01-16/MP-01-16

M-22/MP-22

Spring Range. :

0.2-1.0 Kg/cm2

0.4-1.2 Kg/cm2

0.4-2.0 Kg/cm2

0.6-2.2 Kg/cm2

0.8-2.4 Kg/cm2

Air Supply Pressure:

1.4 To 3.0 Kg/cm2 for multi spring actuator

Air Connection:

¼” NPT (F) & 3/8” NPT (F)

Actuator Operating Temperature:

-40oC To +80oC.

Accessories:

Pneumatic Valve Positioner, Electro Pneumatic(E/P) Valve Positioner, Air SMART Positioner Filter Regulator, Air Lock Relay, Volume Booster, Limit Switch, Proximity Switch, Solenoid Valve, Position Transmitter, Quick Exhaust Valve, etc.

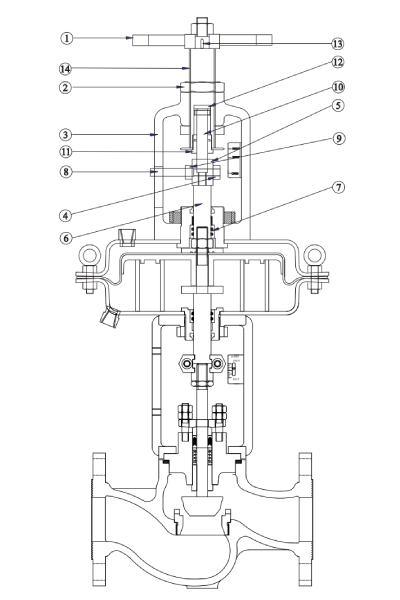

Multi Spring Diaphragm Actuators : Series M

The 'M' Series control valve actuators are diaphragm actuators with pre-compressed multispring construction. They are compact, comparatively with less number of parts, easy to maintain, quickly reversible. The actuators are suitable for regulating and on-off applications. Various models are available covering small to larger thrust requirements. The increasing air pressure supply moves the diaphragm and actuator stem opposing the spring force, while with decreasing air pressure supply the spring force moves the diaphragm in the opposite direction and back to normal position.

To get various loading capacities the number of springs are altered. The actuator can be mounted on the shoulder of control valve bonnet with the help of body studs. The connection between valve stem and actuator stem can be achieved with the help of stem connector made out of two halves. The travel indicator is in built with the stem connector which matches with travel scale indicating the position of inner valve stem.

Max. Diaphragm Pressure

3.5 bar (For Model M and Mp)

Actuator Travel

16 mm, 38 mm.

Diaphragm

Nitrile with Nylon insert / EPDM with Nylon insert (On Request)

Operating Temp. Range

-40 to +80oC Nitrile Elastomers

Connections

1/4" NPT (F) for Models Nos. M-00-16, M-00-16, M-01-16 3/8” NPT (F) for Models Nos. M-22,

Permissible Linearity and Hysterisis

± 5% of Signal Pressure Range

Utility:

Applicable for regulating and on-offfunctions.

High Power:

Variety of models provide choice for low and high thrust requirements

Construction:

Due to multispring arrangement the actuators are lightweight and compact.

Reversible:

The actuators are field reversible without demanding addition or deletion of parts.

Long service life:

Rigid construction and durable components provide a long lasting service life.

Minimum maintenance:

The actuators are virtually maintenance free.

Accuracy :

Rolling diaphragm construction provides constant effective area throughout the stroke.

Manual Operators:

The actuators are also available duly incorporated with Hand Wheel arrangements as Top Mounted configurations.

Accessories Mounting:

Variety of accessories like Valve Positioner, Air Filter Regulator, Air Lock Relay, Volume Booster, Limit / Proximity Switches, Solenoid Valves, Position Feedback Transmitter, Quick Exhaust Valves, I/P Converter, etc. can be mounted easily.

Material of Construction Basic Actuator

|

Part Name |

MOC |

|

Yoke |

Cast Iron |

|

Locking Ring |

Carbon Steel |

|

Seal Box |

Aluminium |

|

Guide Bush |

Teflon Coated Steel Bush |

|

Lower Casing |

Steel (C.R.C. Sheet) |

|

Casing Nuts Bolts |

Carbon Steel + Cadmium Plated |

|

Actuator Diaphragm |

Nitrile With Fabric Insert |

|

Actuator Springs |

Chrome Vanadium Spring Steel |

|

Upper Casing |

Steel (C.R.C. Sheet) |

|

Actuator Stem |

SS 410 + Chrome Plated |

|

Travel Stopper |

Carbon Steel + Cadmium Plated |

|

Diaphragm Plate |

Aluminium / S.G. Iron |

|

'O' Seal Ring (stem To Seal Box) |

Nitrile |

|

Exhaust Nipple |

Carbon Steel |

Top Mounted Handwheel (TMH)

Dembla Top Mounted Handwheel (TMH) is capable of providing operating force in both upward and downward directions and is a continuously connected handwheel. In this arrangement there is nothing to engage or disengage. It can be used to operate the control valve throughout its stroke, or as a travel stop, limiting the amount of closing or opening of the valve.

The actuator is operable with pneumatic air when the handwheel is set in 'NEUTRAL' position. A lock nut is provided to lock the position of the handwheel.The handwheel yoke is provided with a stroke indicator which shows the position of the handwheel mechanism. In addition to it an usual stroke indicator is fixed to the actuator yoke showing valve stem position.

|

Sr No. |

Part Name |

MOC |

|

01 |

Handwheel |

Cast Iron |

|

02 |

TMH Yoke Lock Nut |

Carbon Steel |

|

03 |

TMH Yoke |

Cast Iron |

|

04 |

TMH Stem Connector Allen Bolt |

Carbon Steel |

|

05 |

TMH Stem Connector |

Carbon Steel |

|

06 |

Extension Rod For Actuator Stem |

SS 410 + Hard Chrome Plated |

|

07 |

'O' Seal Ring (Stem To Seal Box) |

Nitrile / Viton |

|

08 |

Stop Peg |

Carbon Steel |

|

09 |

Stop Peg Hex Nut |

Carbon Steel |

|

10 |

TMH Stem |

SS 410 + Hard Chrome Plated |

|

11 |

TMH Screw Nut |

Carbon Steel |

|

12 |

Thrust Washer |

Gun Metal |

|

13 |

Hand wheel Key |

En8 |

|

14 |

Hand wheel Spindle |

SS 410 |

Application Industries

FPSO

Mining

Sugar Mills

Paper and Pulp

Water

Power Plants

Petrochemicals

Oil and gas

Gas Process

Ship Building

Chemicals & Natural Gas

Piping Systems

Pharmaceuticals

Food & Beverage

Global Presence of Dembla

Dembla is one of the major Manufacturer, Exporter and Supplier of Ball Valve, Butterfly Valve, Globe Control Valve, Globe Valve, Check Valve, Gate Valve, DBB Valve, Dual Plate Check Valve, in Italy, Germany, France, Japan, Brazil, Chile, Canada, Australia, Indonesia, Philippines, Vietnam, Africa, Spain, Turkey, Netherlands, UK and across the Entire Globe.

Our Manufacturing set up is situated at Bhiwandi, Thane - Mumbai, Maharashtra, India.