- Home

- About

- Products

-

Globe Control Valve

Butterfly Valve

Ball Valves

Gate Valve

Globe Valve

- Products

- Global Presence

- Customer Care

- Our Client

- Career

- Contact Us

- Download

- Enquiry

Size & Rating

150#

36 Inch | DN 900

300#

30 Inch | DN 750

600#

24 Inch | DN 600

900#

12 Inch | DN 300

1500#

12 Inch | DN 300

Description

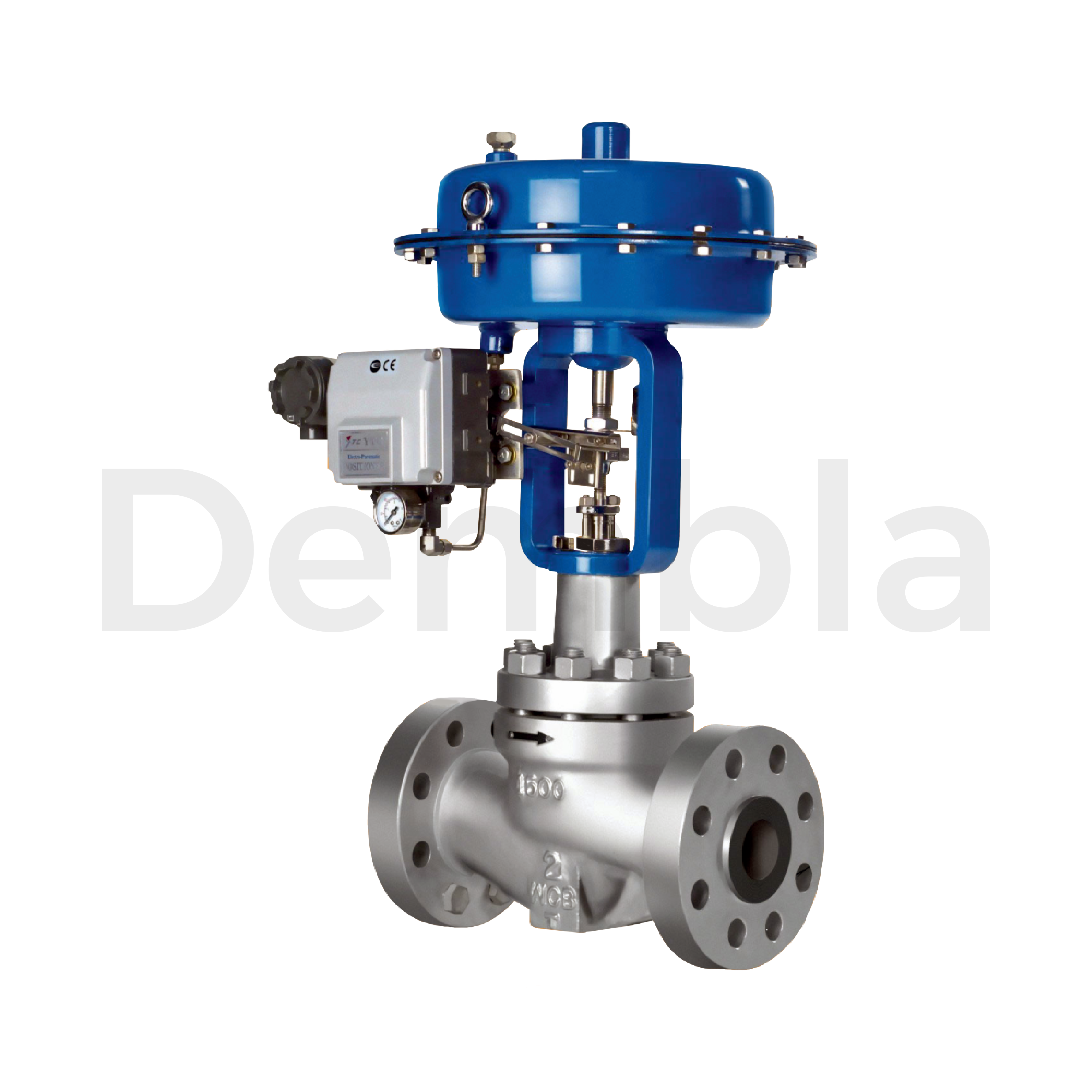

Dembla Two Way Globe Control Valves Are Available in a Wide Range Of Materials, Sizes, Trim Forms And Other Features. A Comprehensive List Of Features Is Available For Immediate Navigation.

Series 1100 valves are Globe two-way single seated body design valves, which satisfy the majority of control applications for process and power industries. Body with top entry trim and bolted bonnet facilitates easy access to all internal parts for online inspection, maintenance and trim replacement. Streamlined flow paths provide large flow capacity.

Features

Precision Control its forte

It is excellent in handling clean fluids, Gases and Steam.

Noise abating Trim designs available.

Anti Cavitation & flashing trim designs available

Multi Spring diaphragm & Compact design

Positioners

Cryogenic application valve available

Design

ASME-B-16.34, SFS EN 12516-2

F/F

ISA 75.08.01, B16.10

Testing

FCI70-2

End Connection

FLANGE-B16.5,B16.47, B2220, IS 6392,EN1092-1

SCREWED & SOCKET-B16.11

BUTTWELD-B16.25

Temperature

-196oC to +600oC

Flow Characteristics

Standard Trim- Linear, Equal Percentage, On-off

Modified Equal Percentage available on request

Cv Values

Refer Tables 2A, 2B, 2C and 2D

Bonnets

Manual Overrides

Top mounted version up to size 4"

Side mounted version recommended above size 4"

Accessories

Pneumatic Valve Positioner, Electro Pneumatic (E/P) Valve Positioner, Air Filter Regulator, Air Lock Relay, Air Volume Booster, Limit Switch, Proximity Switch, Solenoid Valve, Position Transmitter, Quick Exhaust Valve, Volume Tank. etc

Material

|

MATERIAL |

CASTING |

FORGING |

|

CARBON STEEL |

A216 Gr. WCB, A217 Gr. WC6, A217 Gr. WC9 |

A105 |

|

LOW TEMP CARBON STEEL |

A352 Gr. LCB, A352 Gr. LCC |

A350 Gr. LF2 |

|

STAINLESS STEEL |

A351 Gr. CF8M, A351 Gr. CF8, A351 Gr. CF3M, A351 Gr. CF3 |

A182 Gr. F316, A182 Gr. F304, A182 Gr. F316L, A182 Gr. F304L |

|

DUPLEX |

A995 Gr. 4A |

A182 Gr. F51 |

|

SUPERDUPLEX |

A995 Gr. 5A, A995 Gr. 6A |

A182 Gr. F55 |

|

HAST C |

A494 Gr. CW-12MW |

B574 UNS N10276 |

|

ALLOY 20 |

A351 Gr. CN7M |

B462 Gr. N08020 |

|

BRONZE |

B62 Gr. C83600 |

|

|

ALUMINIUM BRONZE |

B148 Gr. A |

B150 Gr. C62300 |

|

NICKEL AL BRONZE |

B148 Gr. D |

B150 Gr. C62300 |

|

TITANIUM |

B381 |

B381 |

|

MONEL |

MONEL 400, MONEL K-500 |

MONEL 400, MONEL K-500 |

|

NICKEL |

INCONEL 625, INCONEL 825, INCONEL 718, INCONEL X750 |

Application Industries

FPSO

Mining

Sugar Mills

Paper and Pulp

Water

Power Plants

Petrochemicals

Oil and gas

Gas Process

Ship Building

Chemicals & Natural Gas

Piping Systems

Pharmaceuticals

Food & Beverage

Size & Rating

150#

36 Inch | DN 900

300#

36 Inch | DN 900

600#

24 Inch | DN 600

900#

16 Inch | DN 400

1500#

12 Inch | DN 300

2500#

8 Inch | DN 200

Description

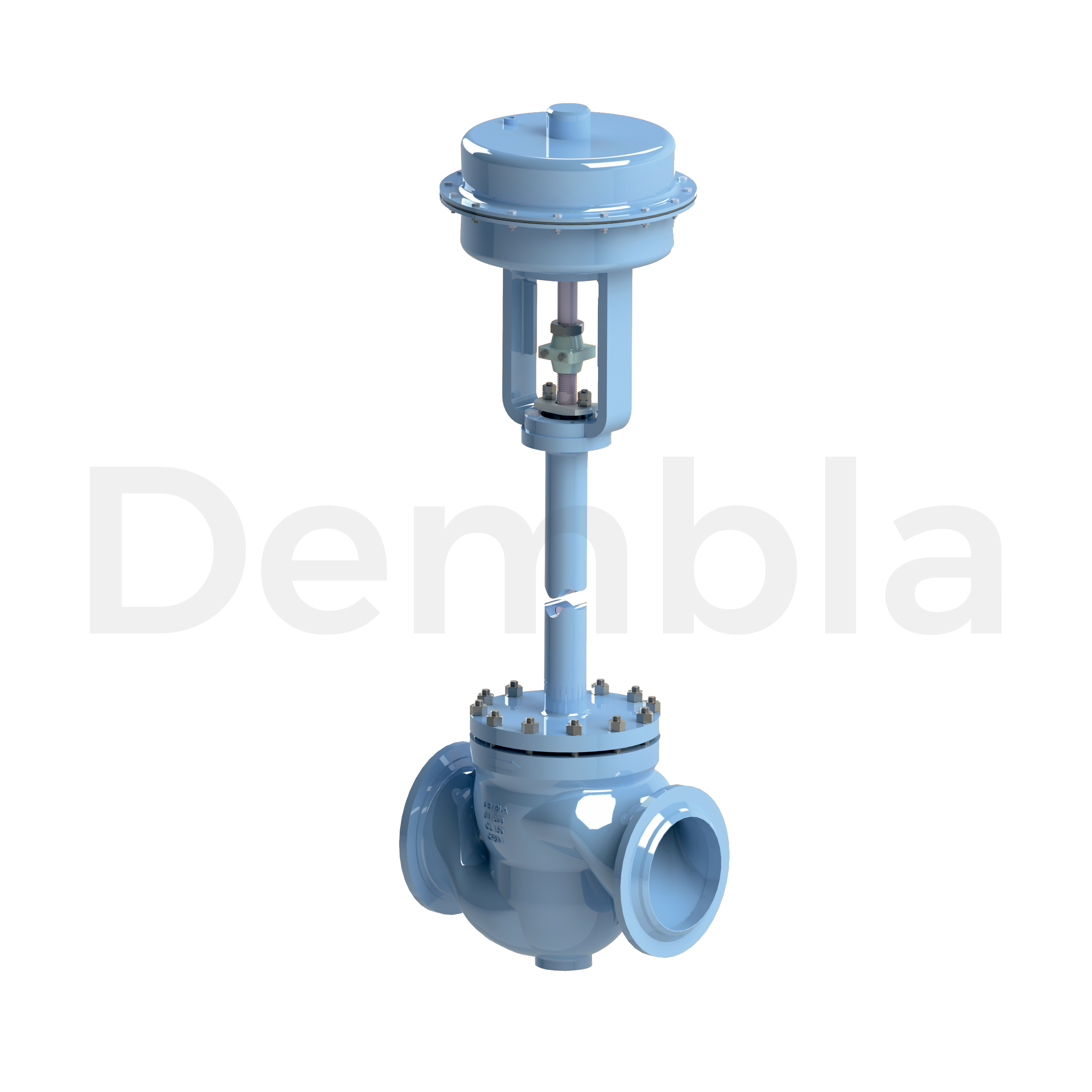

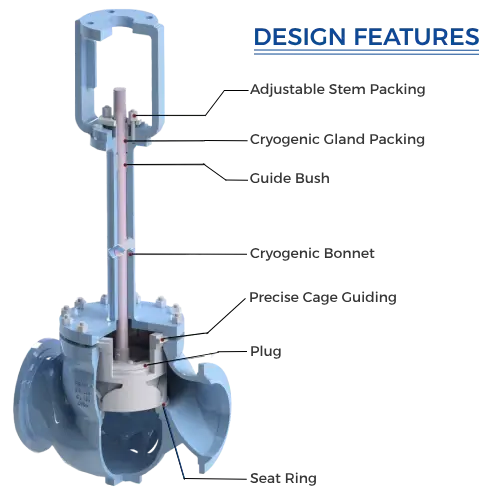

Dembla Cryogenic Globe Control Valves are designed & manufactured to exceed the highest industry standards. These Cryogenic Valves are designed to provide control of liquid and gases where cryogenic temperature may reach up to -196oC. When required, these valves can reliably provide tight shut-off for special applications. The optimized geometry of the these valve bodies presents smooth curves and a flow passageway nearly constant, which reduce the flowing fluid turbulence and increase the valve flow rate capacity. These valves are available in a range of configurations meeting various specifications and can deliver excellent performance.

Features

Height of the extended bonnet suitably designed to keep away stuffing box from cryogenic surfaces. This avoids the failure of seals due to low temperature effect.

Right selections & testing of materials are basics for good performance of cryogenic valves. This is done meticulously for low temperature service suitable for -196oC.

Varieties of trim options are available to match the different process applications.

Design

BS 6364, API 16.34

Face to Face

SA 75.08, ASME B16.10

Flange End

ASME B16.5

Test and Inspection

FCI 70-2, BS 6364, MESC SPE 77/200, MSS SP-134

Material

Limiting Temperature

A352 LC3

-101oC

A351 CF8

-254oC

A351 CF8M

-254oC

A351 CF3

-254oC

A351 CF3M

-254oC

Seat / Seal Selection

Properties |

PCTFE |

PTFE |

PEEK |

|

Temperature Range °C (°F) |

-385~328 (-150 ~-200) |

-328~392 (-150 ~-200) |

-148~500 (-100~-260) |

|

Pressure Rating |

150# - 1500# |

150# - 600# |

150# - 2500# |

|

Mechanical Properties |

Hardness (D) |

75 ~ 85 |

55 ~ 60 |

≥ 82 |

Tensile Strength (MPa) |

31.4 ~ 37.5 |

28 ~ 40 |

≥ 95 |

|

Tensile Elongation (Break, %) |

50 ~ 200 |

> 350 |

≥ 55 |

|

Physical Properties |

Specific Gravity (g/cm3) |

2.11 ~ 2.16 |

2.16 ~ 2.18 |

1.3 ~ 1.4 |

Water Absorption, 24 hrs. (%) |

0.00 |

0.00 |

0.2 |

|

Water Absorption Saturation |

< 0.01 |

<0.01 |

0.5 |

|

Service Application |

Cryogenic & Low Temperature |

Chemical & Low Temperature |

High Pressure & Temperature |

|

Application Industries

Oil and gas

Power Generation

Chemical

Petrochemicals

Marine