- Home

- About

- Products

-

Globe Control Valve

Butterfly Valve

Ball Valves

Gate Valve

Globe Valve

- Products

- Global Presence

- Customer Care

- Our Client

- Career

- Contact Us

- Download

- Enquiry

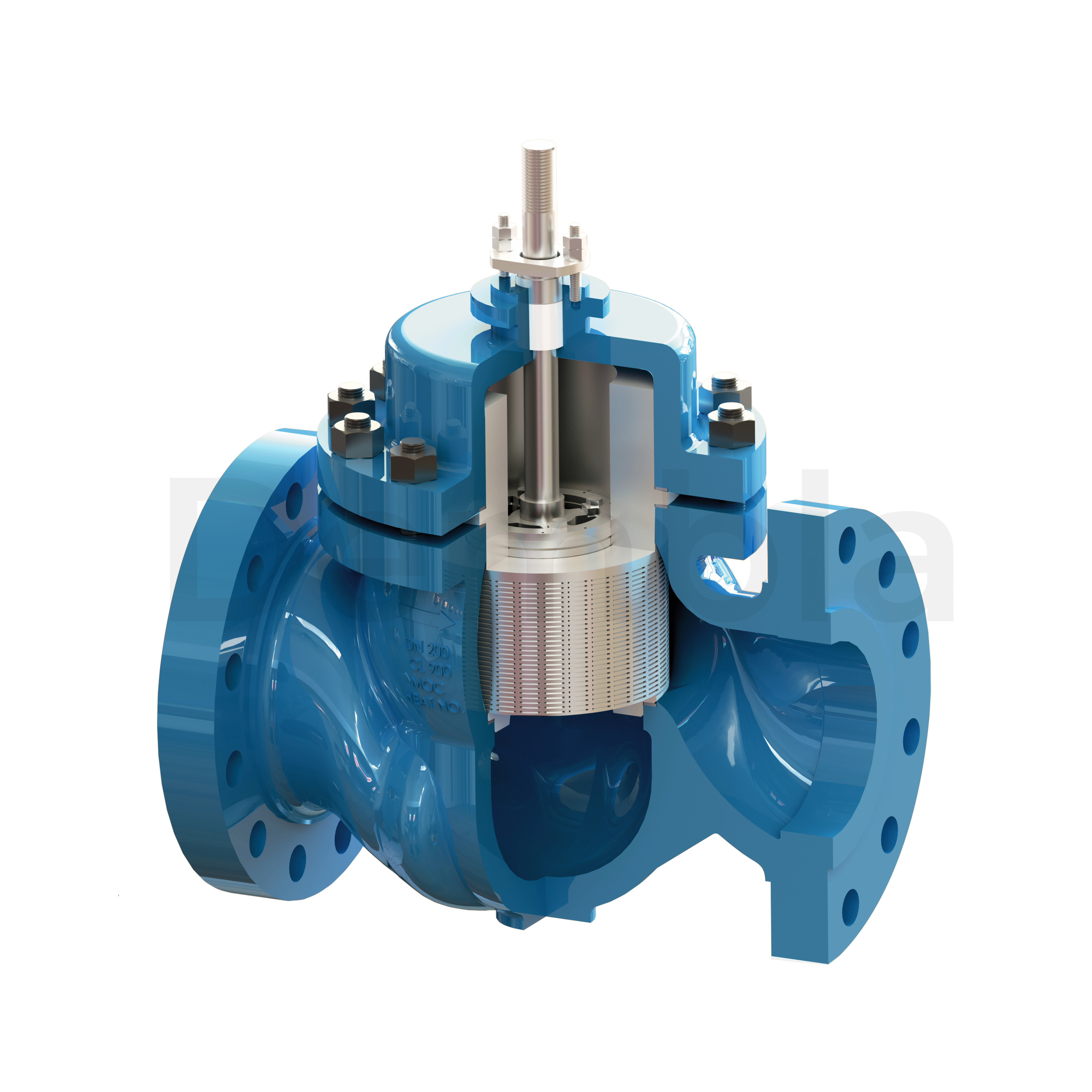

Description

The Series 1800 High Pressure control valves with multi-path stacked disk trim designed to provide heavy path resistance to control high pressure drop & to reduce trim exit velocities this design eliminates cavitation, reduces noise to acceptable limit & controls trim exit jet velocities.

Benefits

Vibration free operation

Eliminate cavitation

Longer cycles between maintenance

Wide control rangeability

Eliminate costly leakage losses

Reduce fluid velocity

Low noise

Improve reliability

Provide repeatable shut off

Eliminate costly additional equipment (Baffles, Silencers)

Application

The multipath, multi turn(MsMp) trim is designed to handle high pressure liquid and gases such as steam, water and petroleum products. Some of critical applications which multipath & multi turn trim (MsMp) can handle smoothly are listed below.

Condensate booster pump reticulation

Turbine bypass

Soot blower control

Feed pump reticulation

Steam Generator blow down

Auxiliary Steam

Deaerator level control

Deaerator pegging steam

Steam vent

De-super heating systems

Steam conditioning

Spray water control

Surge relief

Oil & gas chokes

Anti-surge

Pump recirculation

Feed control

Methanol injection

Gas storage

Gas injection

Gas to flare

Water injection

Compressor recycle

Hot oil let down

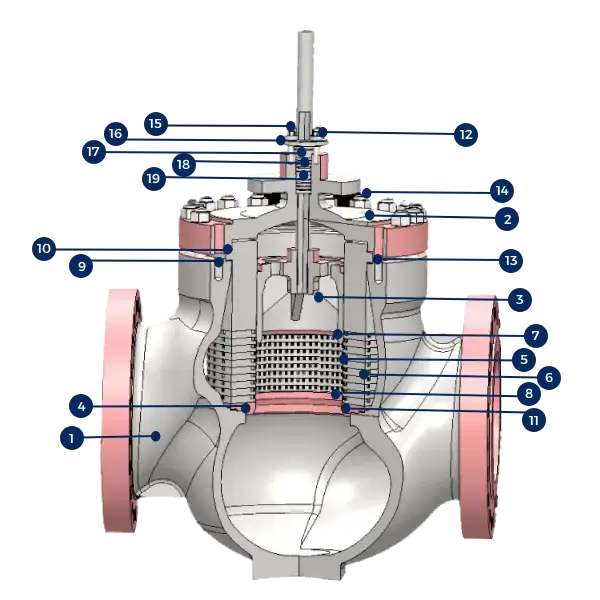

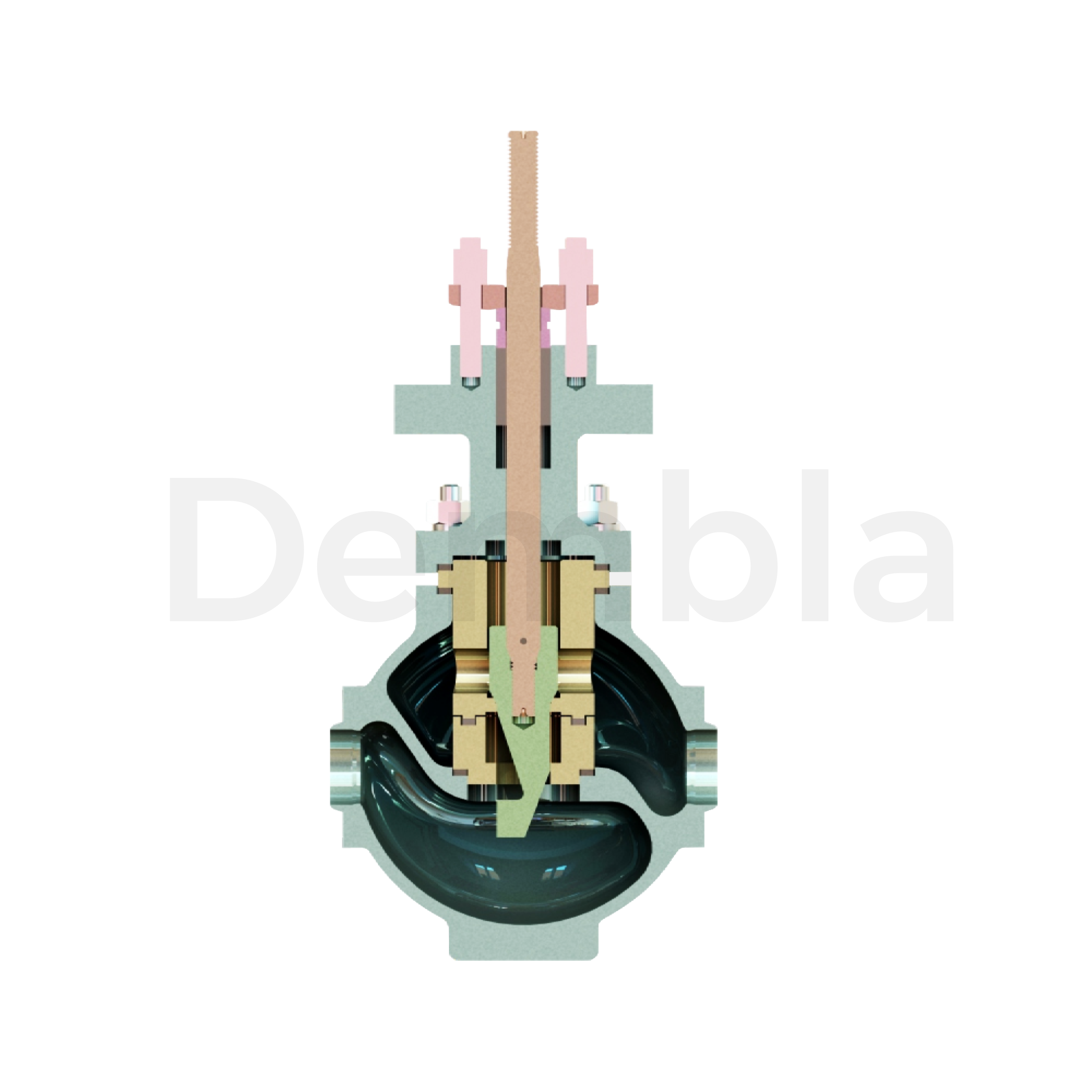

Constructional Drawing

SR NO |

PART NAME |

MATERIAL |

01 |

BODY |

A 216 GR. WCB,WCC A 217WC6, WC9, A 351 CF8, CF8M A 351 CF3, CF3M, A 351 CN7M |

02 |

BONNET |

|

03 |

VALVE PLUG |

SS 316, SS 316 STELLITED, SS 420, 17-4 PH, SS 316 |

04 |

SEAT RING |

SS 316, SS 316 STELLITED, SS 420, SS 316 +PTFE |

05 |

CAGE |

SS 316 + HARD CROME PLATED SS 420 |

06 |

STACK DISC |

SS 316 CP |

07 |

DISK TOP PLATE |

SS 316 |

08 |

DISC BOTTOM PLATE |

SS 316 |

09 |

SOFT SEAL |

PTFE |

10 |

PRESSURE SEAL |

GLASS-FILLED PTFE |

11 |

SEAT GASKET |

SS + GRAPHITE PTFE, GRAPHITE |

12 |

STEM |

SS 316, SS 316 STELLITED, SS 420, 17-4 PH, SS 316 |

13 |

BODY / BONNET GASKET |

SS + GRAPHITE PTFE, GRAPHITE |

14 |

STUD NUT |

A 193 Gr.B7 / 2H |

15 |

GLAND STUD |

ASTM A193 Gr.B8 / 8 |

16 |

GLAND FLANGE |

SS 316 |

17 |

PACKING GLAND |

SS 316 |

18 |

GLAND PACKING |

PTFE |

19 |

LANTERN RING |

SS 316 |

Description

The Series 1600 offers globe valves with multi stage trim, this specially designed low noise anti-cavitation cage-guided trim controls high & moderate pressure differential & it provides fine flow control. It is used to control a wide variety of clean liquids and gases. The series 1600 allows single cage to six cage trim options. its cage-guided design eliminates plug vibration and provides smooth performance, Series-1600 offers a quick change design for easy maintenance. The multi caged design is best to control moderate & high pressure drop which may cause cavitation erosion, vibration & noise.

Benefits

Eliminate cavitation

Low noise

Vibration free operation

Controlled trim exit fluid velocity

Improve reliability

Wide control range ability

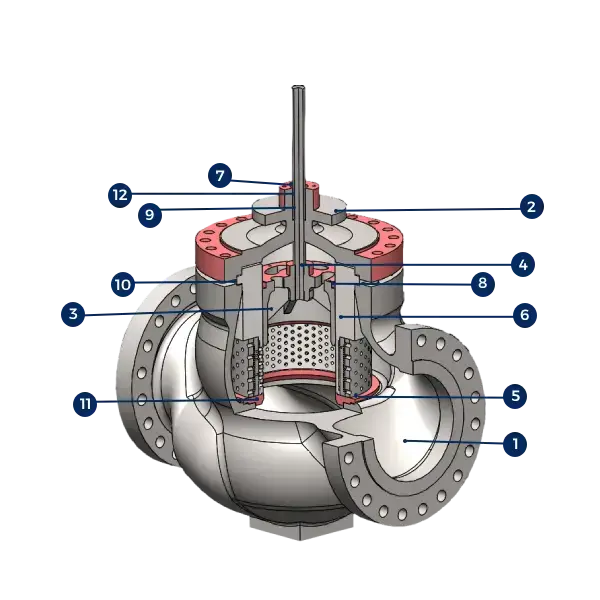

Constructional Drawing

SR NO |

PART NAME |

MATERIAL |

01 |

BODY |

A 216 GR. WCB,WCC A 217WC6, WC9, A 351 CF8, CF8M A 351 CF3, CF3M, A 351 CN7M |

02 |

BONNET |

|

03 |

PLUG |

SS 316, SS 316 STELLITED, SS 420, 17-4 PH |

04 |

STEM |

SS 316 |

05 |

SEAT |

SS 316 |

06 |

CAGE |

SS 316 + HARD CROME PLATED |

07 |

PACKING GLAND |

SS 316 |

08 |

BALANCE SEAL |

GLASS-FILLED PTFE |

09 |

PACKING SPACER |

SS 316 |

10 |

BODY/ BONNET GASKET |

SS + GRAPHITE |

11 |

SEAT GASKET |

SS + GRAPHITE PTFE, GRAPHITE |

12 |

PACKING SET |

PTFE (V-PACKING) |

Trim Option

This specialised valve performs exceptionally well in severe service drop tends to be high in the controlling position but where high capacity through puts at low pressure drops are also required.

It offers a balance between cavitation protection and valve capacity in high-pressure, liquid letdown applications.

It is a well-suited option for applications with custom flow characteristics and custom capacity requirements combined with severe cavitation conditions caused by high-pressure drops

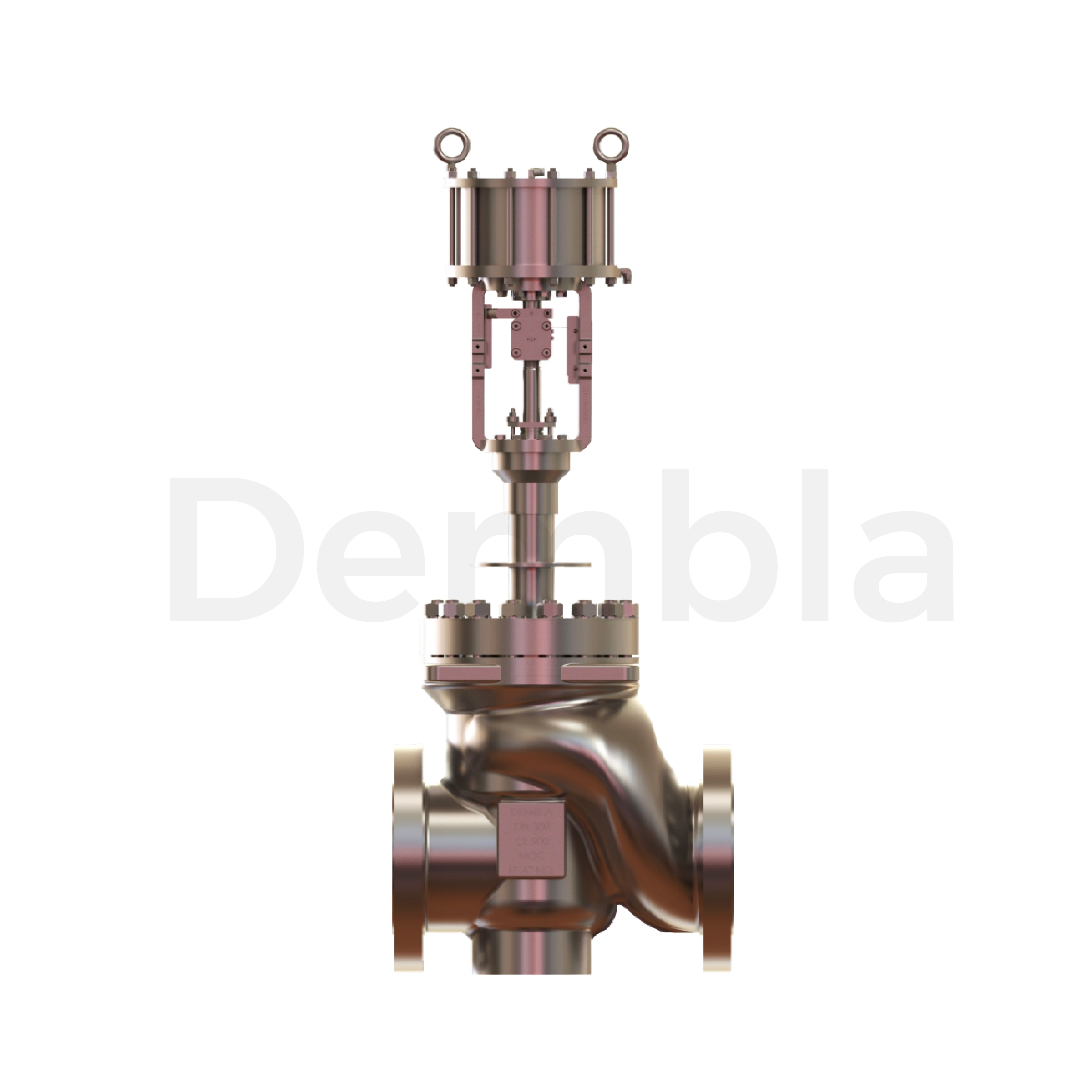

Cryogenic Sliding-Stem Control Valves

Cryogenic valves are globe-style, single-port, valves featuring stainless steel construction materials and extension bonnets. These cryogenic valves are designed to provide throttling or on-off control of liquids and gases at cryogenic temperatures as low as -198oC (-325o F) When required, these rugged valves can reliably provide tight shutoff for special applications within the chemical and hydrocarbon processing industries, such as certain liquified natural gas services. The high-capacity valves with pressure-balanced trim allow the use of smaller, lower-cost actuators, reducing installed costs in high-pressure and high-flow-rate applications.

Features

Cryogenic Spring-Loaded Seal Ring—The seal ring and associated valve parts in the valves are specifically designed and manufactured for excellent performance at low temperatures.

Stable Control—Rugged cage guiding in the valves stabilizes the valve plug at all points in its travel to reduce vibration, mechanical noise, and the need for hydraulic snubbers.

Cost Effective Operation and Economical Maintenance—Increased wear resistance of hardened stainless steel trim means long-lasting service. Balanced valve plug construction in valves permits use of smaller, lower-cost Dembla actuators.

Cryogenic Design Features—The stainless steel valve body and extension bonnet are designed to meet low temperature requirements. The unique metal-to-metal seat design provides repeatable tight shutoff, reducing maintenance costs.

Rugged Metal Seat—The metal-to-metal seat is designed and manufactured to provide long-lasting, reliable, tight shutoff at both ambient and cryogenic temperatures without the need for periodic lapping. This reduces the need for soft seats, even in applications with stringent shut off requirements.

Thoroughly Tested—Extensive cryogenic testing during the development of the valve design reduces the need for expensive cold testing for most applications, which results in quicker delivery and greater value.

Easy Maintenance—Quick-change trim, with a clamped-in seat ring, reduces the disassembly/ assembly time. The valve body can stay in the pipeline during removal of trim parts for inspection or maintenance.

Application

Typical LNG applications

1. Separator level control valve

2. Compressor anti surge control valve

3. Pressure throttling valve etc.

Features

Series 1610 (Multistage Multistep Trim) Ideal for selection with fluids having contaminated particles.

Design confirming to ASME 16.34, IEC 60534-2-5.

Excellent flow control rangeability.

Modified linear flow characteristic.

Leakage class up to class V for metal seating & class VI for soft seating special design.

Leakage class as per FCI 70.2.

NACE MR 0103 and MR0175 compliance.

Erosion, vibration resistant and anti-noise trim design.

Available in globe and angle types.

Flowed over the plug

Excellent solution to erosion, vibration & high noise levels in handling high pressure fluids because of large flow passage and fluid cutting action provided by multiple steps, these valves are well suited for application involving fluid particles where drilled hole multistage and disc stack valves would fail.

Nominal sizes up to 100mm, pressure class #600 to #2500

Temperature -196oC to 650oC

Available up to 6 stages.

Flow Characteristics

Our engineering team employs modern engineering tools, including 3D Modelling, Finite Element Analysis and CFD analysis to guarantee that our products are designed with the utmost integrity and reliability. Thanks to ongoing Research & Development and the integration of the latest engineering tools, Dembla's Severe Service Valves represent the forefront of control valve technology.

Applications

Dembla series 1610 Multi step design are capable of handling high pressure drops without instability problems.

These are suitable where multistage multi hole control valve fails either because of micro flow rates and where the contaminated fluid would cause blockage of drilled holes.

Multistep trims design has modified linear inherent characteristic and has excellent range ability

Valve Size (1) |

Pressure Class (2) |

||||

inches |

DN |

600 |

900 |

1500 |

2500 |

1 & 1.5 |

25 & 40 |

|

|

|

|

2 |

50 |

|

|

|

|

3 |

80 |

|

|

|

|

4 |

100 |

|

|

|

|

6 |

150 |

|

|

|

|

8 |

200 |

|

|

|

|

1. Sizes, ratings and end connections are available in both globe and angle body styles.

2. Pressure classes shown represent ASME/ANSI ratings and equivalent PN ratings.

Standard Capacity – 3-Stage Design Flow Characteristic: MODIFIED LINEAR

Value Size |

|

Orifice Diameter |

Travel |

Trim C |

Min.Cont. CV |

inches |

DN |

mm |

mm |

Cv |

|

1 |

25 |

17.8 |

6.35 |

2.0 |

0.05 |

1.5 |

40 |

25.4 |

6.35 |

3.8 |

0.10 |

2 |

50 |

38.1 |

9.65 |

9.0 |

0.15 |

3 |

80 |

57.2 |

15.7 |

20 |

0.25 |

4 |

100 |

73.2 |

19.1 |

34 |

0.43 |

6 |

150 |

105 |

25.4 |

65 |

0.56 |

8 |

200 |

137 |

31.8 |

135 |

1.0 |

Flow Characteristic: MODIFIED LINEAR

Valve Size |

|

Orifice Diameter |

Travel |

Trim CV1 |

Trim CV2 |

Trim CV3 |

inches |

DN |

mm |

mm |

CV |

CV |

CV |

1 |

25 |

17.8 |

6.35 |

1.0 |

1.4 |

1.7 |

1.5 |

40 |

25.4 |

6.35 |

1.9 |

2.5 |

3.2 |

2 |

50 |

38.1 |

9.65 |

4.5 |

6.0 |

7.5 |

3 |

80 |

57.2 |

15.7 |

10 |

13 |

16.5 |

4 |

100 |

73.2 |

19.1 |

16.5 |

22 |

28 |

6 |

150 |

105 |

25.4 |

34 |

45 |

56 |

8 |

200 |

137 |

31.8 |

70 |

90 |

115 |

Flow Characteristic: MODIFIED LINEAR

Value Size |

|

Orifice Diameter |

Travel |

Trim CV1 |

Trim CV2 |

Trim CV3 |

inches |

DN |

mm |

mm |

Cv |

Cv |

Cv |

1 |

25 |

17.8 |

6.35 |

0.80 |

1.0 |

1.4 |

1.5 |

40 |

25.4 |

6.35 |

1.4 |

1.8 |

2.5 |

2 |

50 |

38.1 |

9.65 |

3.5 |

4.5 |

6.0 |

3 |

80 |

57.2 |

15.7 |

7.5 |

9.5 |

13 |

4 |

100 |

73.2 |

19.1 |

12 |

16 |

22 |

6 |

150 |

105 |

25.4 |

25 |

33 |

45 |

Global Presence of Dembla

Dembla is one of the major Manufacturer, Exporter and Supplier of Ball Valve, Butterfly Valve, Globe Control Valve, Globe Valve, Check Valve, Gate Valve, DBB Valve, Dual Plate Check Valve, in Italy, Germany, France, Japan, Brazil, Chile, Canada, Australia, Indonesia, Philippines, Vietnam, Africa, Spain, Turkey, Netherlands, UK and across the Entire Globe.

Our Manufacturing set up is situated at Bhiwandi, Thane - Mumbai, Maharashtra, India.